New well foundation concept, as used at a Norwegian Sea well

This summary is based on insights from the paper "New Well Foundation Concept, as Used at a Norwegian Sea Well," presented at the SPE Arctic and Extreme Environments Conference & Exhibition, Moscow, 2011. The original paper was authored by Trond Sivertsen, SPE, Det Norske Oljeselskap ASA, and Harald Strand, SPE, NeoDrill AS. The full paper can be accessed via the Society of Petroleum Engineers.

Essential Highlights

CAN Technology Overview: The Conductor Anchor Node (CAN) is a new suction anchor-type well foundation designed to support heavy blowout preventers (BOPs) and Christmas trees. It offers high load capacity and enhances well stability, especially in deepwater and Arctic conditions.

Operational Benefits:

Pre-Rig Installation: Allows conductor installation before the rig arrives, reducing rig time and top-hole construction costs.

Accidental Load Mitigation: Provides a high bending stiffness, directing accidental loads above the BOP, thus protecting the well structure.

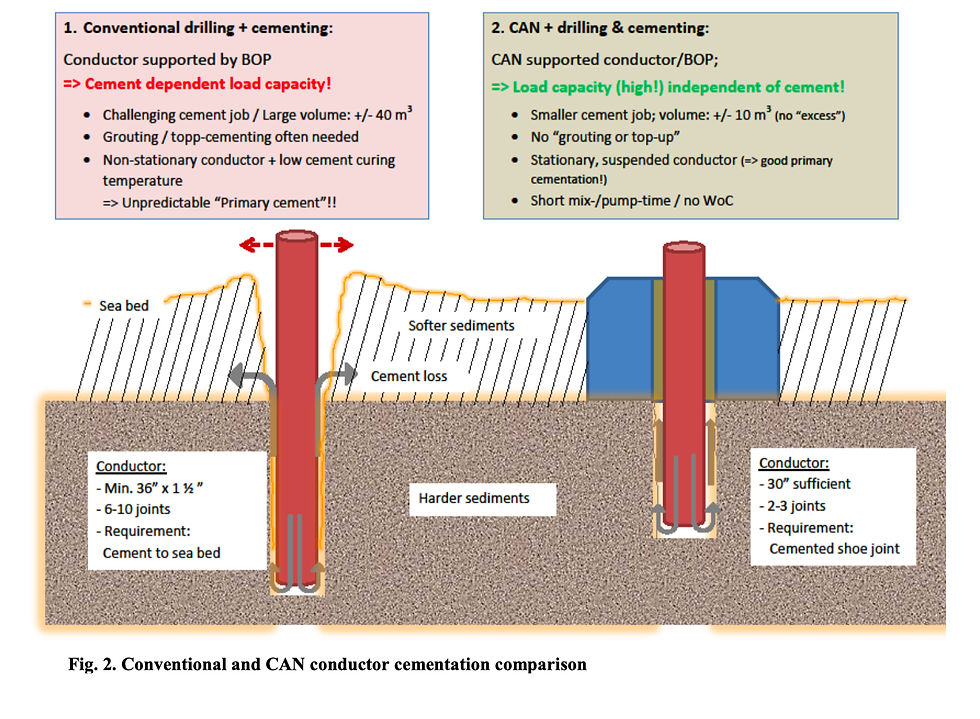

Enhanced Cementing: Shorter conductors and improved conditions lead to better cement quality and reduced cement volume.

Environmental and Safety Advantages:

Reduced Environmental Footprint: Smaller vessels emit less CO2 and NOx, and there is reduced cuttings and cement disposal.

Improved HSE Performance: "Hands-free" conductor installation minimizes manual handling and enhances safety.

Field Applications: Demonstrated in water depths of 270-1150 meters on the Norwegian Continental Shelf, achieving successful installation even in challenging seabed conditions.

Versatility and Reusability: The CAN units are durable and can be reused for multiple well installations, providing cost efficiency over time.

Abstract

A new well foundation system, the Conductor Anchor Node (CAN), has been developed to improve well stability and safety, particularly for handling heavy Blow Out Preventers (BOPs) in deep water and arctic environments. The CAN mitigates fatigue risks and accidental overloads, such as rig drive-offs, by providing substantial load capacity through its large cross-sectional area and soil interaction. It also reduces environmental impacts by limiting cuttings and cement disposal, which is critical in sensitive marine areas. The CAN enables pre-rig conductor installation, cutting rig time and top-hole construction costs, and has been successfully deployed in multiple full-scale applications on the Norwegian Continental Shelf.

Introduction

As rig day rates rise, there is a growing need to reduce rig time, particularly for drilling the top-hole section of wells, which doesn't require pressure control. To address this, a more efficient conductor installation method is needed. Additionally, current well designs lack the capacity to handle accidental loads, such as those caused by rig drive-offs, which can result in wellhead failures. The Conductor Anchor Node (CAN) was developed as a solution, allowing for pre-rig conductor installation and providing mechanical support. The CAN enhances the well's lateral load capacity and transfers potential damage points above the BOP, protecting the wellhead and conductor from accidental overloads.

Technology description

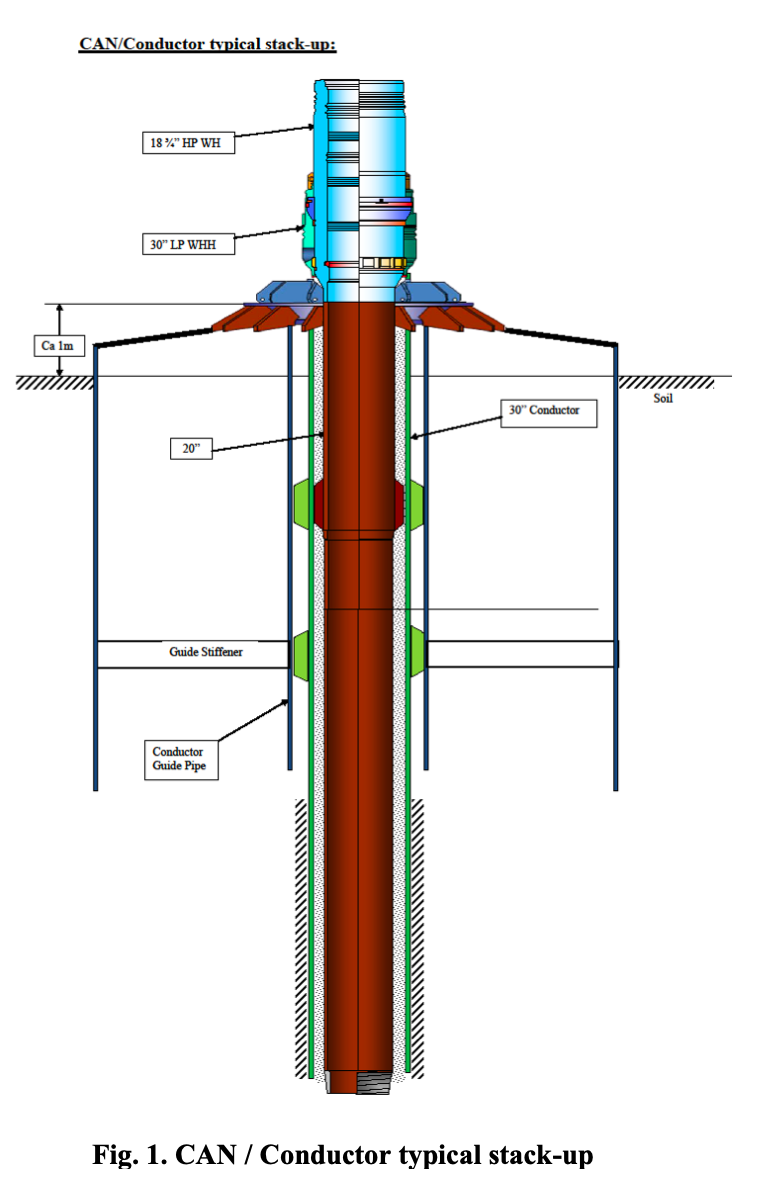

The Conductor Anchor Node (CAN) is a suction anchor designed to improve well stability, featuring a cylindrical shell with a strong lid and a conductor guide that extends into the soil. The CAN, weighing 60-80 tons, is installed using a DP vessel with a heave-compensated crane. Once placed on the seabed, an ROV pumps out water from the CAN, creating pressure that pushes it further into the sediment, providing substantial load capacity. The large surface area allows for high push-in forces with moderate pressure, optimizing installation efficiency.

The CAN also enables efficient pre-rig conductor installation. The conductor is pre-assembled onshore, lifted by a crane, and stabbed into the CAN, allowing for cost-effective installation without the need for drilling and cementing. Alternatively, the conductor can be installed by jetting, with the CAN providing stability and predictability for shorter conductors. The CAN offers superior load capacity, reducing cement usage and well construction costs while mitigating environmental impact through less waste and emissions.

Key advantages include high axial and lateral load capacity, increased bending stiffness, reduced well fatigue, and safe conductor installation. This technology supports faster production and lower top-hole construction costs while ensuring safer and more efficient well operations.

Operational experience

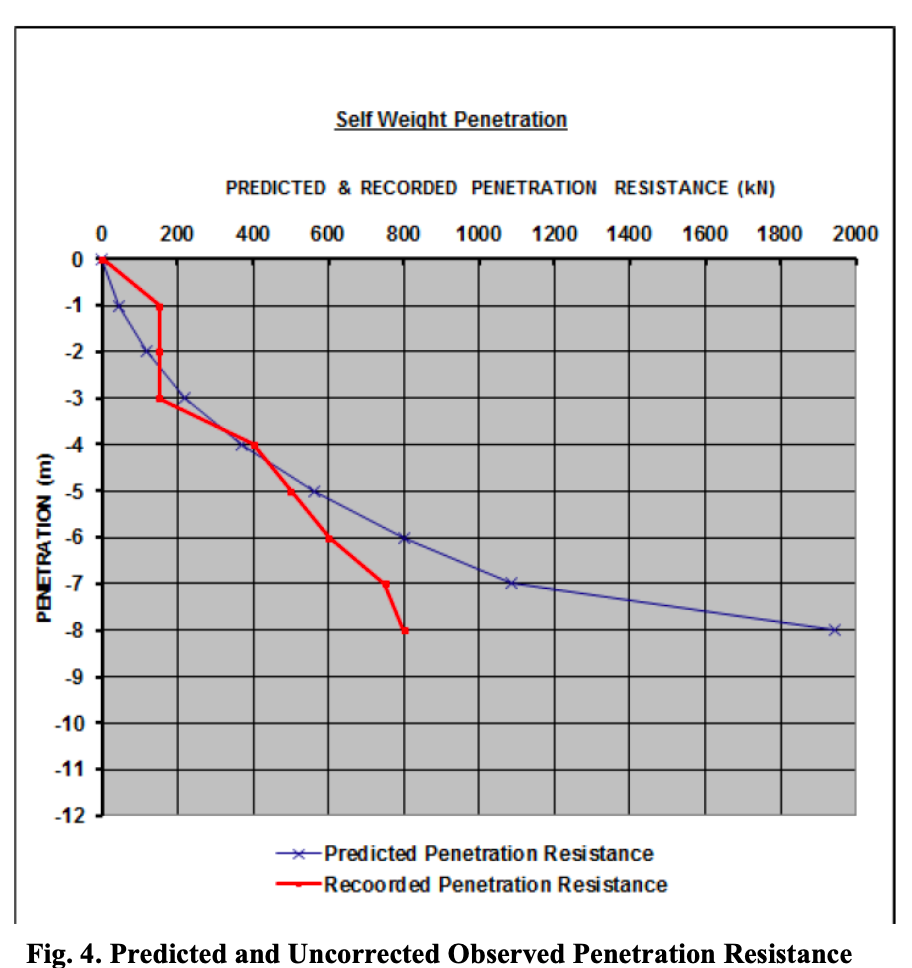

CAN Installation

The CAN installation was successfully completed in less than 20 hours at a soft seabed location, ensuring high load capacity to support the heavy BOP of the Aker Barents rig. The CAN was installed with two transponders for accurate placement, achieving nearly full penetration (10.5m vs. 11m). A pressure differential of 2 bar generated about 550 tons of push-in force, testing the CAN's vertical load capacity. The installation weather window required 4 hours with <3.5m HS, and ROV operations were successfully performed. The conductor was drilled, installed, and cemented without issue, significantly reducing cement volume and time.

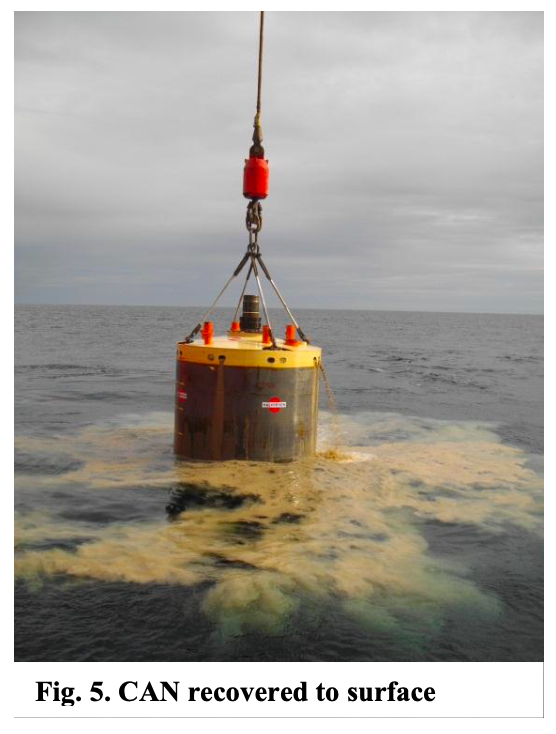

CAN Recovery

After drilling, the well was plugged, and the CAN was recovered by reversing the installation process. The ROV pumped water into the CAN, lifting it 60% of its embedded length before being fully freed from the seabed. The CAN, along with the cut 30” and 20” conductors, was lifted to the surface and placed onboard. The recovery process went as planned, with the CAN and components cleaned and prepared for reuse.

HSE Performance

Safety precautions were taken by installing bumper bars to control the CAN’s landing on the vessel deck. A 10 cm thick clay layer indicated high steel/soil friction during recovery. The entire operation was completed without any HSE incidents, demonstrating the CAN's ability to be installed and recovered safely. The “hands-free” conductor handling method improved work conditions for the crew, reducing manual labor on the rig. The CAN installation by vessel also minimized the environmental footprint by reducing emissions and cuttings disposal, using smaller vessels.

Conclusions

The CAN concept offers safer and more cost-efficient well construction by enabling the installation of higher load capacity wells compared to conventional methods. Its superior bending stiffness ensures accidental loads are directed above the BOP. In arctic and cold climates, the CAN reduces conductor length and cement volume, shortens cement jobs, and improves cement quality by keeping the conductor motionless during setting. Additionally, the CAN reduces the environmental footprint of conductor installation, making it a more sustainable alternative to traditional rig installations.

Acknowledgement

Det norske Oljeselskap’s active participation in preparing and planning this demonstration project, which resulted in technically high quality execution of the vessel operations, were highly appreciated by all parties involved.

For more detailed technical information, the full paper is available through the Society of Petroleum Engineers.

References

Sivertsen, T., & Strand, H. (2011). New Well Foundation Concept, as Used at a Norwegian Sea Well. Presented at the SPE Arctic and Extreme Environments Conference & Exhibition, Moscow, Russia, 18–20 October. SPE-149548-MS. Retrieved from Society of Petroleum Engineers.

Comentarios